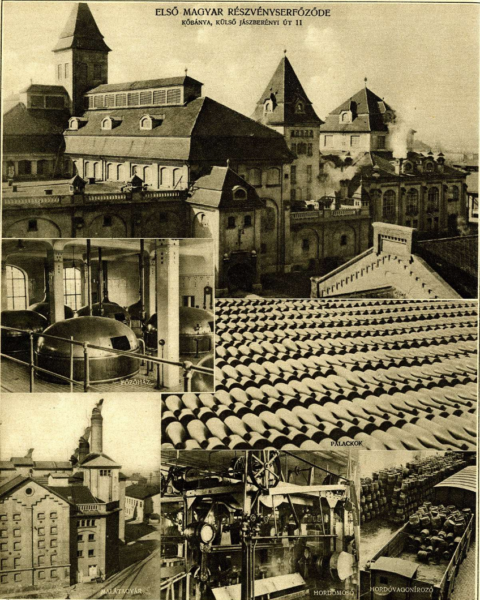

First Hungarian share brewery

The development of the domestic brewing industry flourished in the second half of the 19th century thanks to the activities of Antal Dreher. He was the one who, taking advantage of the opportunities of the time, founded the first large-scale brewery of the Habsburg Empire in Schwechat and later in Budapest, as the development of transport, steam engines, railways and shipping made it possible to transport beer over much greater distances in a unit of time than in previous centuries. At the same time, an important feature of large-scale brewing was the switch from the former ale to lager-style beer, which differed from the previous beers both in its recipe and in its production technology, as it required cellars and ice to cool it until the invention of artificial refrigeration.

The Barber and Klusemann brewery was built next to Dreher's factory in Kőbánya at about the same time as the previous one, and in the 1860s it was transformed into a joint-stock company, in which members of the Haggenmacher dynasty, liquor manufacturers such as the Gschwindt family, and prominent figures from the catering and hotel industry were also present. The phylloxera epidemic created a particular boom for the brewing industry, which also allowed for continuous quantitative and qualitative improvements and beer production.

So in the 1870s, the factory was modernised to compete with the nearby Dreher factory. The need for renovation can also be deduced from the company's stock market listing, since in 1867 the value of a share was nearly 700 forints, while in 1877 it was only 206 forints, but after the renovation it started to rise again and by 1894, when the first board of directors' report is available from the archives, the price of a share was already 1,543 forints. It was at this time that the factory began to expand and develop not only internally but also in the surrounding area. For example, they bought part of the cellars of the surrounding quarry plots, while the production in 1894 was 314 236 hl of beer, and they expanded in several parts of the country and established beer warehouses, including in Miskolc in the same year. This level of production was mostly constant at this time, only seasonal effects (such as bad weather in summer) could reduce the amount of beer produced and sold, but even with these fluctuations the company was still decidedly profitable with an average annual profit of HUF 300 000 (while the share capital was HUF 900 000).

In 1900, the introduction of the crown brought a new form of taxation on beer, which, combined with the economic downturn at the beginning of the decade, brought the brewery a period of crisis, but not dangerously bad years. Their rural depot was enlarged with the one in Oradea, while in 1901 Linde's cooling technology, which had been in existence for 30 years, was introduced to the plant, so that they no longer had to keep the ice on the Danube from wintering. In 1904 a depot was also established in Debrecen, while, together with the start of the domestic labour movements, the management complained more and more about the ever-rising wages and raw material costs. These complaints, however, were not reflected in the company's balance sheets and results, as profits averaged between 500,000 and 850,000 crowns during the decade, while the share price rose steadily to 7,150 crowns by 1911.

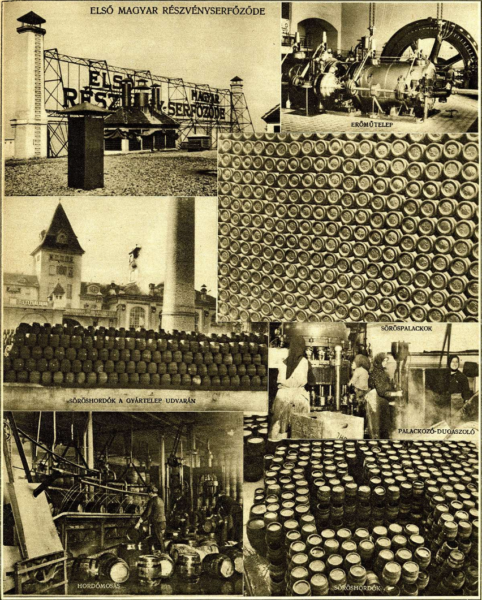

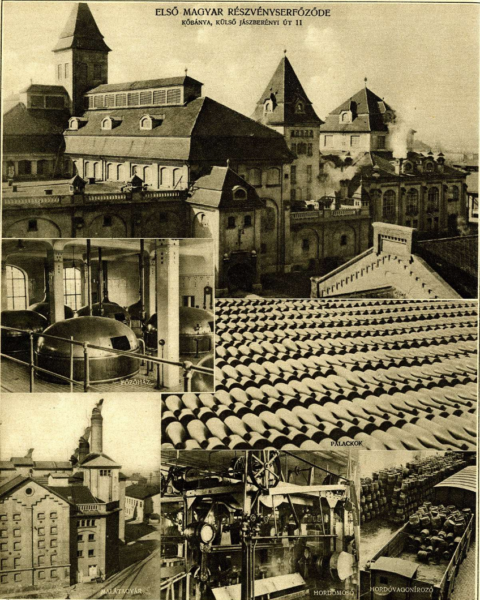

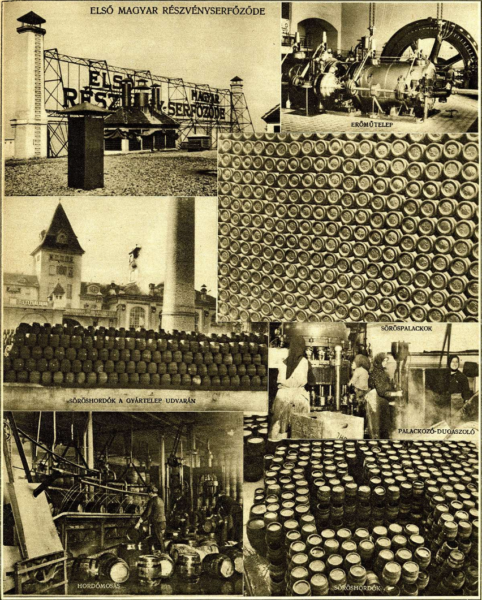

Despite the success of the plant, a loan of 2 million crowns was taken from the Hungarian National Central Savings Bank in 1910, and a depot was set up in Petrozsény, and in 1911 in several places in Budapest and Nagykároly. They also got rid of the shares of the Kőbánya Malt Factory Ltd., which they had bought for 277 200 crowns and sold for K 735 578. The first half of the 1910s was accompanied by a new technological development, so that before the war the factory's bottling plant and barrel-press were built, while the entire yard was covered with ceramite.

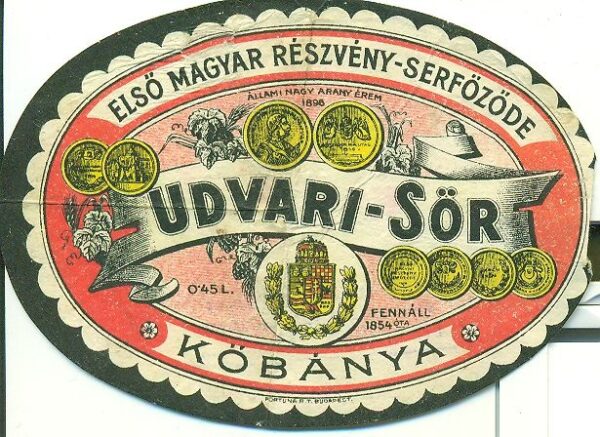

The First Hungarian Share Brewery, the first joint-stock company in the brewing industry, was established in Kőbánya by the owners of the mills in Pest in 1867, as the successor of the Barber and Klusemann brewery in Kőbánya, which had been in existence since 1854.

It maintained its independence for 56 years, but could not compete with factories like Dreher and Haggenmacher. In 1923, it entered into a community of interests with them, and in 1933, together with the Haggenmacher factories, it was merged into Dreher Antal Serfőzdéi Rt. and became part of Dreher-Haggenmacher Erste Magyar Részvényserfőzde Rt.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

During the war, they faced a continuous shortage of labour and raw materials, although on the occasion of the company's 50th anniversary in 1917, wages and housing allowances were increased by 25%.By 1922, however, it became clear that the breweries concentrated in Budapest were too big for the Hungarian market, which had shrunk to one third of its former size, while they could not export to their former markets in the Aisantium and beyond due to the general closure of foreign trade. The company's records also show that Hungarian beer was seen as a political, revisionist product in the countries of the Lesser Antilles, and that this was one of the reasons why they were discouraging exports. It was this realisation that led the Részvényswerwerfde to join the Concentracio, a community of interest association of domestic beer companies led by the Dreher-Haggenmacher brewery. The participating breweries, as separate companies but with a common will, managed the domestic beer production, optimised their production and jointly exploited their potential. Although cartel agreements existed before the war, this was a higher level of cooperation, which was soon followed by joint ventures. Thus, together with Johann Liebieg & Co. of Reichenberg, they founded Liebieg Budapest Textile Works Ltd. with 30 000 spindles, Maul Cocoa and Chocolate Factory Ltd. with Maul of Wernigerode and acquired an interest in the glass factory of Count László Károlyi, as well as in the Asbestos Chemical and Technical Articles Factory Ltd. And in 1924 they started the production of Dreher brandy and Dreher rum, and then built a new liqueur factory with the Amsterdam company Wijnand Fockink.

By 1926, it was clear that they had lost their previous markets for good, so they turned to malt, one of the semi-finished products of the brewing industry, in addition to lateral expansion, and successfully exported to all continents of the world, but especially to the countries of Europe. Germany, Italy, the Netherlands and Switzerland became the top destinations for the brewery's malt exports, while a cowshed was set up to use the brewing waste (yeast, spent grain) and to make a profit from milk sales. In the meantime, they were also able to modernise the Dreher-Haggenmacher brewery in Oradea.

In 1927, they bought into the hotel business and acquired the majority ownership of Hungaria Nagyszálloda Rt. and thus the Dunapalota (Ritz Hotel) and the National Hotel.In 1928, they also acquired the Király Serfőzdet in Nagykanizsa, which had become bankrupt due to the loss of the southern ends. However, production in 1929 was hampered by a very high beer tax of 15 pence per hectolitre (at today's prices, this would be around 45-50 000 forints, whereas today the same tax is around 3 500 ft.) The other problem was the transport difficulties, as the Aisantium countries, but especially Yugoslavia, applied tariffs for malt exports which made it 3-4 times more expensive to transport malt from Budapest to Fiume by rail than from non-Hungarian areas hundreds of kilometres further away.

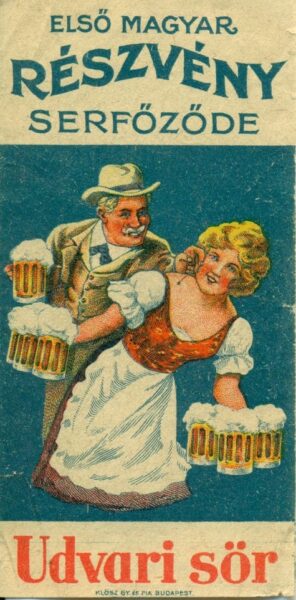

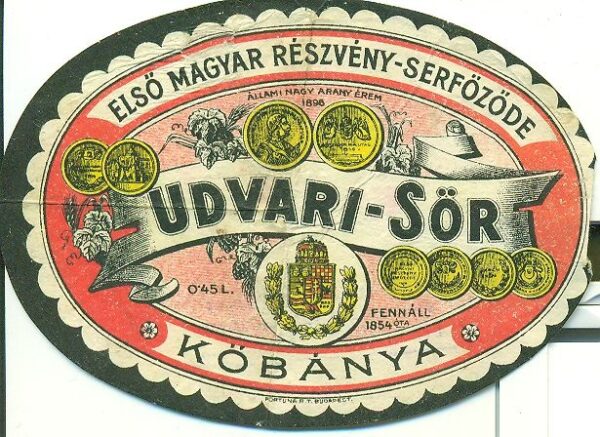

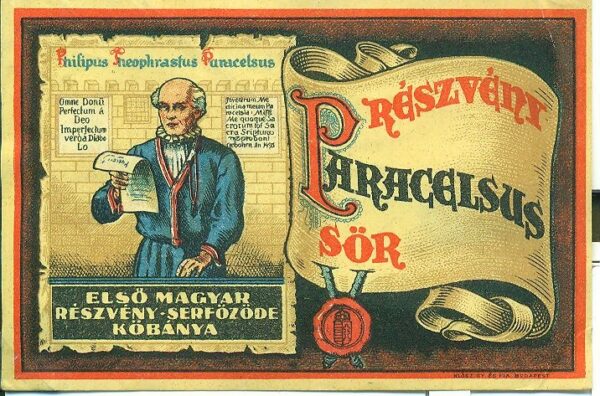

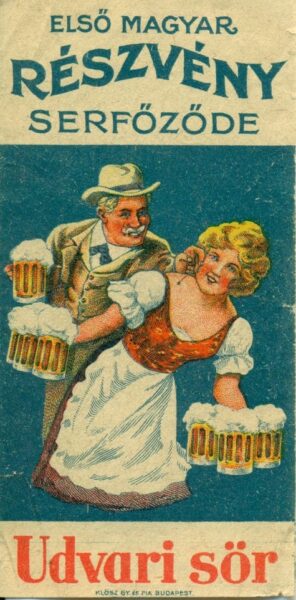

Inscription: first Hungarian Share Serfőzde. The First First Finnish Beer Company.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

The Great Depression hit the breweries in 1931, but this was mainly to their advantage, as they were able to buy up bankrupt companies, such as the entire assets of Liebieg, which was renamed Dreher-Haggenmacher Textilművek Rt. At the same time, the hotel industry felt the impact of the decline in tourism. Finally, the crisis reached the factories and on 1 October 1933 the three companies involved in the Concentration were merged to form Dreher-Haggenmacher Erste Magyar Részvényserfőzde Rt.

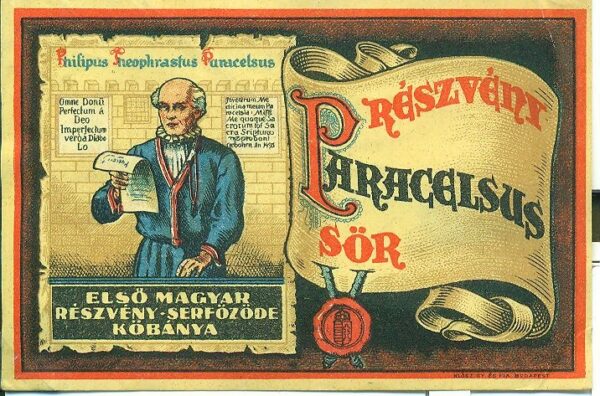

In 1934, the new plant started to produce carbonated and mineral waters together with the Szent Lukács Spa, and in 1937 they bought 12 Mária Valéria Street from the Pesti Lloyd Company, which was converted into a hotel and apartments.In 1938 they managed to export malt (with Hungarian ships) to overseas in larger quantities, but the outbreak of the European wars created new difficulties for the company. Nevertheless, in 1943 Paracelsus Rt. was established to produce brewer's yeast for the domestic market, but the war in Hungary prevented it from taking off. With nationalisation, the company was first merged with Kőbányai Polgári Serfőző Rt and other companies, and then split up according to territorial criteria. Thus, even today's Dreher and Sopron factories are legal successors, or at least the spiritual heirs of the former Share Factory.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

Sources:

Hungarian National Archives. National Archives. Z 1247. Documents of the First Hungarian Share Brewery

Date of foundation: 1867

Date of cessation: 1933

Securities issued:

| First Hungarian share brewery |

Decisive leaders:

1867-1877 | Ágoston Barber |

1878-1879 | József Kunig |

1880-1890 | Knight Miksa Brüll |

1891-1905 | István Mendl |

1906-1909 | Károly Gomperz |

1910-1919 | Dr. József Schmidt |

1920-1926 | Dr. Jenő Kunz |

1927-1933 | Jenő Dreher |

Author: by Dr. Márton Pelles

Date of foundation: 1867

Founders are not set

Decisive leaders:

1867-1877 | Ágoston Barber |

1878-1879 | József Kunig |

1880-1890 | Knight Miksa Brüll |

1891-1905 | István Mendl |

1906-1909 | Károly Gomperz |

1910-1919 | Dr. József Schmidt |

1920-1926 | Dr. Jenő Kunz |

1927-1933 | Jenő Dreher |

Main activity not set

Main products are not set

Seats are not configured

Locations are not set

Main milestones are not set

Author: by Dr. Márton Pelles

First Hungarian share brewery

The development of the domestic brewing industry flourished in the second half of the 19th century thanks to the activities of Antal Dreher. He was the one who, taking advantage of the opportunities of the time, founded the first large-scale brewery of the Habsburg Empire in Schwechat and later in Budapest, as the development of transport, steam engines, railways and shipping made it possible to transport beer over much greater distances in a unit of time than in previous centuries. At the same time, an important feature of large-scale brewing was the switch from the former ale to lager-style beer, which differed from the previous beers both in its recipe and in its production technology, as it required cellars and ice to cool it until the invention of artificial refrigeration.

The Barber and Klusemann brewery was built next to Dreher's factory in Kőbánya at about the same time as the previous one, and in the 1860s it was transformed into a joint-stock company, in which members of the Haggenmacher dynasty, liquor manufacturers such as the Gschwindt family, and prominent figures from the catering and hotel industry were also present. The phylloxera epidemic created a particular boom for the brewing industry, which also allowed for continuous quantitative and qualitative improvements and beer production.

So in the 1870s, the factory was modernised to compete with the nearby Dreher factory. The need for renovation can also be deduced from the company's stock market listing, since in 1867 the value of a share was nearly 700 forints, while in 1877 it was only 206 forints, but after the renovation it started to rise again and by 1894, when the first board of directors' report is available from the archives, the price of a share was already 1,543 forints. It was at this time that the factory began to expand and develop not only internally but also in the surrounding area. For example, they bought part of the cellars of the surrounding quarry plots, while the production in 1894 was 314 236 hl of beer, and they expanded in several parts of the country and established beer warehouses, including in Miskolc in the same year. This level of production was mostly constant at this time, only seasonal effects (such as bad weather in summer) could reduce the amount of beer produced and sold, but even with these fluctuations the company was still decidedly profitable with an average annual profit of HUF 300 000 (while the share capital was HUF 900 000).

In 1900, the introduction of the crown brought a new form of taxation on beer, which, combined with the economic downturn at the beginning of the decade, brought the brewery a period of crisis, but not dangerously bad years. Their rural depot was enlarged with the one in Oradea, while in 1901 Linde's cooling technology, which had been in existence for 30 years, was introduced to the plant, so that they no longer had to keep the ice on the Danube from wintering. In 1904 a depot was also established in Debrecen, while, together with the start of the domestic labour movements, the management complained more and more about the ever-rising wages and raw material costs. These complaints, however, were not reflected in the company's balance sheets and results, as profits averaged between 500,000 and 850,000 crowns during the decade, while the share price rose steadily to 7,150 crowns by 1911.

Despite the success of the plant, a loan of 2 million crowns was taken from the Hungarian National Central Savings Bank in 1910, and a depot was set up in Petrozsény, and in 1911 in several places in Budapest and Nagykároly. They also got rid of the shares of the Kőbánya Malt Factory Ltd., which they had bought for 277 200 crowns and sold for K 735 578. The first half of the 1910s was accompanied by a new technological development, so that before the war the factory's bottling plant and barrel-press were built, while the entire yard was covered with ceramite.

The First Hungarian Share Brewery, the first joint-stock company in the brewing industry, was established in Kőbánya by the owners of the mills in Pest in 1867, as the successor of the Barber and Klusemann brewery in Kőbánya, which had been in existence since 1854.

It maintained its independence for 56 years, but could not compete with factories like Dreher and Haggenmacher. In 1923, it entered into a community of interests with them, and in 1933, together with the Haggenmacher factories, it was merged into Dreher Antal Serfőzdéi Rt. and became part of Dreher-Haggenmacher Erste Magyar Részvényserfőzde Rt.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

During the war, they faced a continuous shortage of labour and raw materials, although on the occasion of the company's 50th anniversary in 1917, wages and housing allowances were increased by 25%.By 1922, however, it became clear that the breweries concentrated in Budapest were too big for the Hungarian market, which had shrunk to one third of its former size, while they could not export to their former markets in the Aisantium and beyond due to the general closure of foreign trade. The company's records also show that Hungarian beer was seen as a political, revisionist product in the countries of the Lesser Antilles, and that this was one of the reasons why they were discouraging exports. It was this realisation that led the Részvényswerwerfde to join the Concentracio, a community of interest association of domestic beer companies led by the Dreher-Haggenmacher brewery. The participating breweries, as separate companies but with a common will, managed the domestic beer production, optimised their production and jointly exploited their potential. Although cartel agreements existed before the war, this was a higher level of cooperation, which was soon followed by joint ventures. Thus, together with Johann Liebieg & Co. of Reichenberg, they founded Liebieg Budapest Textile Works Ltd. with 30 000 spindles, Maul Cocoa and Chocolate Factory Ltd. with Maul of Wernigerode and acquired an interest in the glass factory of Count László Károlyi, as well as in the Asbestos Chemical and Technical Articles Factory Ltd. And in 1924 they started the production of Dreher brandy and Dreher rum, and then built a new liqueur factory with the Amsterdam company Wijnand Fockink.

By 1926, it was clear that they had lost their previous markets for good, so they turned to malt, one of the semi-finished products of the brewing industry, in addition to lateral expansion, and successfully exported to all continents of the world, but especially to the countries of Europe. Germany, Italy, the Netherlands and Switzerland became the top destinations for the brewery's malt exports, while a cowshed was set up to use the brewing waste (yeast, spent grain) and to make a profit from milk sales. In the meantime, they were also able to modernise the Dreher-Haggenmacher brewery in Oradea.

In 1927, they bought into the hotel business and acquired the majority ownership of Hungaria Nagyszálloda Rt. and thus the Dunapalota (Ritz Hotel) and the National Hotel.In 1928, they also acquired the Király Serfőzdet in Nagykanizsa, which had become bankrupt due to the loss of the southern ends. However, production in 1929 was hampered by a very high beer tax of 15 pence per hectolitre (at today's prices, this would be around 45-50 000 forints, whereas today the same tax is around 3 500 ft.) The other problem was the transport difficulties, as the Aisantium countries, but especially Yugoslavia, applied tariffs for malt exports which made it 3-4 times more expensive to transport malt from Budapest to Fiume by rail than from non-Hungarian areas hundreds of kilometres further away.

Inscription: first Hungarian Share Serfőzde. The First First Finnish Beer Company.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

The Great Depression hit the breweries in 1931, but this was mainly to their advantage, as they were able to buy up bankrupt companies, such as the entire assets of Liebieg, which was renamed Dreher-Haggenmacher Textilművek Rt. At the same time, the hotel industry felt the impact of the decline in tourism. Finally, the crisis reached the factories and on 1 October 1933 the three companies involved in the Concentration were merged to form Dreher-Haggenmacher Erste Magyar Részvényserfőzde Rt.

In 1934, the new plant started to produce carbonated and mineral waters together with the Szent Lukács Spa, and in 1937 they bought 12 Mária Valéria Street from the Pesti Lloyd Company, which was converted into a hotel and apartments.In 1938 they managed to export malt (with Hungarian ships) to overseas in larger quantities, but the outbreak of the European wars created new difficulties for the company. Nevertheless, in 1943 Paracelsus Rt. was established to produce brewer's yeast for the domestic market, but the war in Hungary prevented it from taking off. With nationalisation, the company was first merged with Kőbányai Polgári Serfőző Rt and other companies, and then split up according to territorial criteria. Thus, even today's Dreher and Sopron factories are legal successors, or at least the spiritual heirs of the former Share Factory.

Hungarian Trade and Hospitality Museum CC BY-NC-SA

Sources:

Hungarian National Archives. National Archives. Z 1247. Documents of the First Hungarian Share Brewery