United Incandescent and Electric Ltd.

The United Incandescent and Electric Light Company was founded in 1896. Its famous manufacturing plant was built in Újpest in 1900, where production of the widely popular tungsten filament filament lamp began in 1907. The development of the company in the first half of the 1910s made it a large corporation, and its steady growth was only marginally affected by the First World War and the Great Depression. After the reconstruction work following the Second World War, the public limited company maintained its reputation during the socialist era.

Originally the United Electricity Limited Company, founded in 1896, it merged in 1897 with the Electric Light Bulb Limited Company, founded in 1888. It was then that it took its final name, the United Electric and Incandescent Lamp Company. The merger was due to the fact that the capital strength of the Incandescent Lamp Company, formerly run by the Egger brothers, had been exhausted by 1895 and its operations were under severe threat from the emergence of competitors. Following the merger, capital and development were all that was needed to create a plant of sufficient size to produce up to 10,000 incandescent lamps a day. It was with this aim in mind that on 28 January 1900, the land on the estate of Count Sándor Károlyi in Újpest was purchased by a joint-stock company. The merged joint-stock company centralised its factories in Újpest, with its factory at 5 Váci út. By the end of 1901, the factory was operating at full capacity, thanks to the installation of the necessary machinery for production, the provision of sewerage and water supply to the factory, and the establishment of its own gas works.

But the most important breakthrough was clearly the purchase of the invention of Sándor Juszt and Ferenc Henemann. They succeeded - after years of experimentation - in producing the first tungsten filament lamp with a relatively long life (800 hours) and high luminous intensity (7.8 lumen/W) compared to carbon filament lamps. In December 1904, the joint-stock company entered into a contract with the inventors to manufacture and sell the tungsten lamp exclusively under the joint-stock company's rights. Mass production started in 1907. In the years before the First World War, the joint stock company was forced to acquire new inventions in order to keep pace with the year-on-year growth in incandescent lamp production. By the early 1910s, the joint stock company's factory had developed into a world-class enterprise with the use of spiralizing and gas filling, and annual production reached 8 million lamps (compared to 2.3 million at the turn of the century). In addition to domestic consumption, the company was able to sell its light bulbs not only in Europe (France, Great Britain, Spain) but also in Japan, Canada and South America, and even had its own factories in Austria, Italy and Russia. It was around this time that the Tungsram brand name was born, which the company has used since 1912. The company's ambitious development led to the establishment of other joint stock companies, including the Fast Telegraph Company, the International Tungsten Lamp Company, the Budafok Electricity Company and the Clara Losonczi Electricity Company.

Thanks to its extensive production capacity and popularity, the First World War did not have a significant impact on the factory's production, as its export products were exported to countries other than the Allies. The few years following the war (1918-1921) were difficult, as the number of incandescent lamps produced fell during this period, only returning to normal levels by 1921. After the First World War, the production profile of the joint-stock company was extended to include the production of electron tubes, which had already been produced during the war years and were intended for radio communications because of the lack of an electricity network. In 1917, experiments for the production of electron tubes were carried out at the Újpest plant, the third in the world to do so, and the success of these experiments allowed production to start at the end of the year. In 1918, the Budapest Telephone Factory built military radios with the electron tubes produced by Tungsram, which were used on the Italian front. In the early 1920s, Tungsram made its own version of the increasingly popular barium tube product, production of which began in 1927. As a result, 1.2 million tubes were produced in 1930. As an indication of the popularity of the joint stock company's products, 75% of the tubes produced were exported. Thanks to continuous improvements, by the 1930s it was possible to make short-wave radio widely available. It is also worth noting that in 1930, thanks to Zoltán Bay, the patent for the crypton gas-filled incandescent lamp became available, and during this period Tungsram was also experimenting with the foundations for the introduction of television in Hungary.

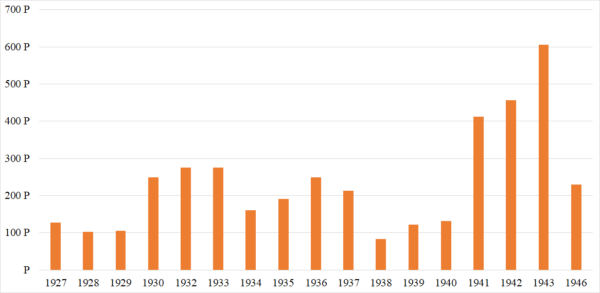

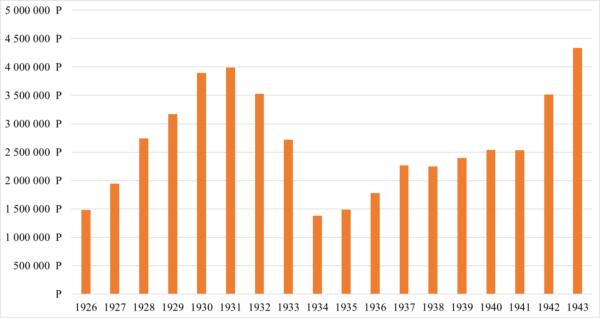

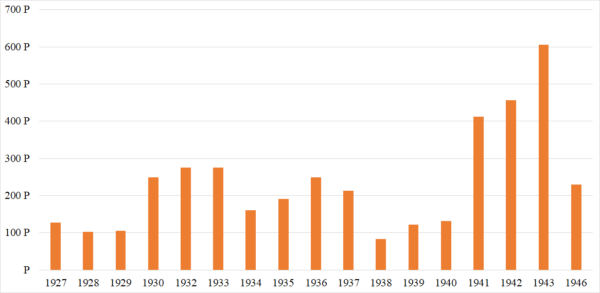

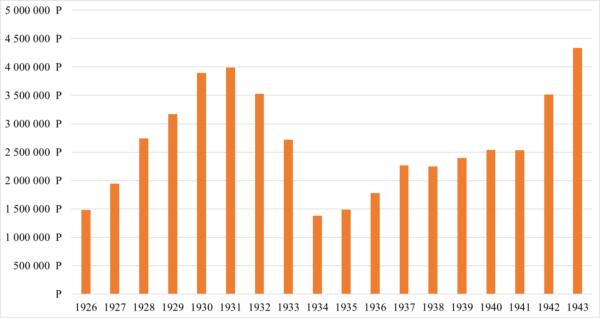

In the post-war years, the joint-stock company bought all the shares of the Tokod Glass Factory Joint-Stock Company and converted the factory into a glass bulb and light bulb factory. In addition, however, it already had a number of interests at that time: these included the Gyorstelegraph Aktiengesellschaft, the Hungarian Glass Works - Jnwald József Aktientársaság; the Vienna Glühlampenfabr. Watt. A-G., and the Zirkon incandescent lamp factory in Warsaw. The success of the company is demonstrated by the variation in its profits and stock exchange price between 1926 and 1943, which shows a significant increase in the period after the First World War and after the Great Depression.

During the Second World War, the factory was severely damaged, and the damage was exacerbated by the fact that some of the workers were victims of the war or emigrated abroad. After the war damage had been repaired, the company continued to operate under the same name and in the same form as a joint-stock company after nationalisation. This was due to the fear of reprisals from the company's foreign shareholders and the fear that Tungsram's foreign interests would be lost for good as a result of state intervention.

The company was acquired by General Electric in 1989 and sold to a private individual in 2018. The COVID-19 pandemic and the subsequent economic crisis caused significant difficulties for the company's operations, requiring government intervention in 2022 to save the company.

Sources

Hungarian Financial Compass 1908-1929.

Kadlecovits Géza: Tungsram. The role of a factory with a long history in Hungarian technical life. The World of Nature. 1987(118), 12. 487-492.

Ákos Koroknai:The first century of Tungsram Rt. 1996. 57-63.

Hungarian Compass 1927-1943.

Press material 1888-1944.

Imre Tóth: 75 years of the United Izzo. Budapest. 1971, 9(12). 12-14.

Founded on 1 August 1896.

Termination time not set

Founders: the Pesti Hungarian Commercial Bank, Niederösterreichische Escompte Gesellschaft, Egger brothers

Decisive leaders:

1908-1921 | Jenő Szabó |

1922-1932 | Henrik Fellner |

1932. | Miksa Krassny |

1933-1941 | Fülöp Weisz |

1942-1944 | Dr. Lajos Walko |

Principal activity: manufacture of electrical equipment (incandescent lamps, telephones, electrical signalling equipment, railway safety equipment)

Main products are not set

Seats:

1908-1921 | Újpest Váci út 77. |

1922-1944 | Budapest V. Fürdő utca 5 |

Locations are not set

Main milestones are not set

Author: Róbert Szabó

Founded on 1 August 1896.

Founders: the Pesti Hungarian Commercial Bank, Niederösterreichische Escompte Gesellschaft, Egger brothers

Decisive leaders:

1908-1921 | Jenő Szabó |

1922-1932 | Henrik Fellner |

1932. | Miksa Krassny |

1933-1941 | Fülöp Weisz |

1942-1944 | Dr. Lajos Walko |

Principal activity: manufacture of electrical equipment (incandescent lamps, telephones, electrical signalling equipment, railway safety equipment)

Main products are not set

Seats:

1908-1921 | Újpest Váci út 77. |

1922-1944 | Budapest V. Fürdő utca 5 |

Locations are not set

Main milestones are not set

Author: Róbert Szabó

United Incandescent and Electric Ltd.

The United Incandescent and Electric Light Company was founded in 1896. Its famous manufacturing plant was built in Újpest in 1900, where production of the widely popular tungsten filament filament lamp began in 1907. The development of the company in the first half of the 1910s made it a large corporation, and its steady growth was only marginally affected by the First World War and the Great Depression. After the reconstruction work following the Second World War, the public limited company maintained its reputation during the socialist era.

Originally the United Electricity Limited Company, founded in 1896, it merged in 1897 with the Electric Light Bulb Limited Company, founded in 1888. It was then that it took its final name, the United Electric and Incandescent Lamp Company. The merger was due to the fact that the capital strength of the Incandescent Lamp Company, formerly run by the Egger brothers, had been exhausted by 1895 and its operations were under severe threat from the emergence of competitors. Following the merger, capital and development were all that was needed to create a plant of sufficient size to produce up to 10,000 incandescent lamps a day. It was with this aim in mind that on 28 January 1900, the land on the estate of Count Sándor Károlyi in Újpest was purchased by a joint-stock company. The merged joint-stock company centralised its factories in Újpest, with its factory at 5 Váci út. By the end of 1901, the factory was operating at full capacity, thanks to the installation of the necessary machinery for production, the provision of sewerage and water supply to the factory, and the establishment of its own gas works.

But the most important breakthrough was clearly the purchase of the invention of Sándor Juszt and Ferenc Henemann. They succeeded - after years of experimentation - in producing the first tungsten filament lamp with a relatively long life (800 hours) and high luminous intensity (7.8 lumen/W) compared to carbon filament lamps. In December 1904, the joint-stock company entered into a contract with the inventors to manufacture and sell the tungsten lamp exclusively under the joint-stock company's rights. Mass production started in 1907. In the years before the First World War, the joint stock company was forced to acquire new inventions in order to keep pace with the year-on-year growth in incandescent lamp production. By the early 1910s, the joint stock company's factory had developed into a world-class enterprise with the use of spiralizing and gas filling, and annual production reached 8 million lamps (compared to 2.3 million at the turn of the century). In addition to domestic consumption, the company was able to sell its light bulbs not only in Europe (France, Great Britain, Spain) but also in Japan, Canada and South America, and even had its own factories in Austria, Italy and Russia. It was around this time that the Tungsram brand name was born, which the company has used since 1912. The company's ambitious development led to the establishment of other joint stock companies, including the Fast Telegraph Company, the International Tungsten Lamp Company, the Budafok Electricity Company and the Clara Losonczi Electricity Company.

Thanks to its extensive production capacity and popularity, the First World War did not have a significant impact on the factory's production, as its export products were exported to countries other than the Allies. The few years following the war (1918-1921) were difficult, as the number of incandescent lamps produced fell during this period, only returning to normal levels by 1921. After the First World War, the production profile of the joint-stock company was extended to include the production of electron tubes, which had already been produced during the war years and were intended for radio communications because of the lack of an electricity network. In 1917, experiments for the production of electron tubes were carried out at the Újpest plant, the third in the world to do so, and the success of these experiments allowed production to start at the end of the year. In 1918, the Budapest Telephone Factory built military radios with the electron tubes produced by Tungsram, which were used on the Italian front. In the early 1920s, Tungsram made its own version of the increasingly popular barium tube product, production of which began in 1927. As a result, 1.2 million tubes were produced in 1930. As an indication of the popularity of the joint stock company's products, 75% of the tubes produced were exported. Thanks to continuous improvements, by the 1930s it was possible to make short-wave radio widely available. It is also worth noting that in 1930, thanks to Zoltán Bay, the patent for the crypton gas-filled incandescent lamp became available, and during this period Tungsram was also experimenting with the foundations for the introduction of television in Hungary.

In the post-war years, the joint-stock company bought all the shares of the Tokod Glass Factory Joint-Stock Company and converted the factory into a glass bulb and light bulb factory. In addition, however, it already had a number of interests at that time: these included the Gyorstelegraph Aktiengesellschaft, the Hungarian Glass Works - Jnwald József Aktientársaság; the Vienna Glühlampenfabr. Watt. A-G., and the Zirkon incandescent lamp factory in Warsaw. The success of the company is demonstrated by the variation in its profits and stock exchange price between 1926 and 1943, which shows a significant increase in the period after the First World War and after the Great Depression.

During the Second World War, the factory was severely damaged, and the damage was exacerbated by the fact that some of the workers were victims of the war or emigrated abroad. After the war damage had been repaired, the company continued to operate under the same name and in the same form as a joint-stock company after nationalisation. This was due to the fear of reprisals from the company's foreign shareholders and the fear that Tungsram's foreign interests would be lost for good as a result of state intervention.

The company was acquired by General Electric in 1989 and sold to a private individual in 2018. The COVID-19 pandemic and the subsequent economic crisis caused significant difficulties for the company's operations, requiring government intervention in 2022 to save the company.

Sources

Hungarian Financial Compass 1908-1929.

Kadlecovits Géza: Tungsram. The role of a factory with a long history in Hungarian technical life. The World of Nature. 1987(118), 12. 487-492.

Ákos Koroknai:The first century of Tungsram Rt. 1996. 57-63.

Hungarian Compass 1927-1943.

Press material 1888-1944.

Imre Tóth: 75 years of the United Izzo. Budapest. 1971, 9(12). 12-14.